-

This is the only farm cooperative grain elevator in northwest Florida.

-

There are three main buildings in the complex. The office is on the left, the grain elevator is immediately behind the office building and the fertilizer house is on the right of the photograph.

-

The elevator is approximately 100 feet tall. There are six silos or individual storage bins attached to the main building.

-

The opening under the main structure is the main access for loading and unloading truck loads of farm products.

-

Trucks enter and stop at the office for a weigh-in to establish the amount of product before unloading.

-

The soybeans are unloaded into "the pit", a 30' underground storage space. Commodities are purchased from the farmers, stored and sold to consumers in amounts up to 5 tons.

-

The same area serves as a loading bay. A flow of corn is released from the storage silo. Customers range from hunters and farmers to sales of corn by the truckload, shipped overseas from the port in nearby Mobile.

-

This small elevator services the main silo.

-

The pipes feed into 18 different bins, storing individual items, such as, wheat oats, milo, soybeans and corn. Corn is the main item in storage at the elevator.

-

The conveyor belt moves corn up to the top floor of the grain elevator. The belt must be cleaned by hand.

-

The conveyor belt runs the length of the bins.

-

An auger turns the dispensing chute.

-

The bins are numbered and the feeding tube is positioned over the correct storage area.

-

White corn dust covers surfaces in the elevator.

-

A spectacular view of Walnut Hill can be seen from the top of the silos. Hundreds of acres of farmland stretch to the northern horizon.

-

Fertilizer is stored, mixed and sold in a seperate building. The bags shown above are loaded by hand after customing the mixture of the elements, such as, amonium nitrate, potash, etc.

-

The bobcat is used to load scoops of ingredients in the fertilizer mix.

-

Clay Stuckey demonstrates one of the tasks in the fertilizer house. The fertilizer is dumped into this grate. A scale weighs the material and it is mixed in a hopper. The finished product is distributed by truckload or by 50 pound bag.

-

Pre-packaged materials in 50 pound bags are stored in the building adjacent to the front office. The bags contain fertilizer and seed, as well as feed for any livestock.

-

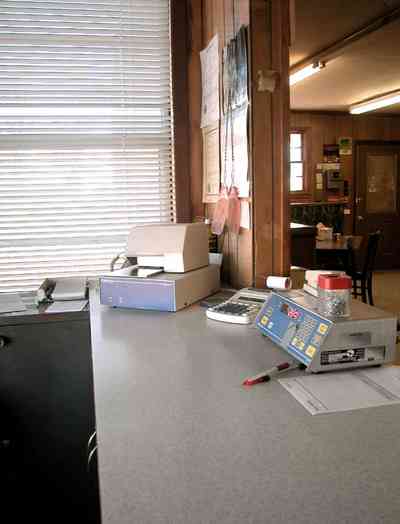

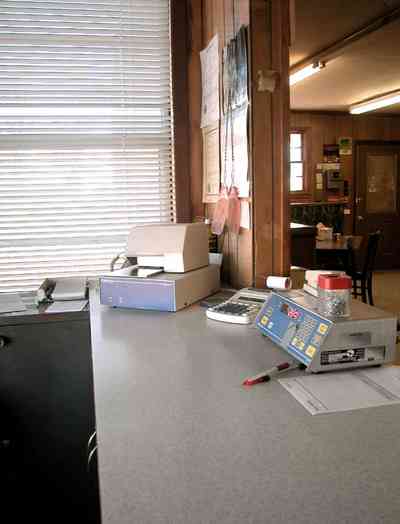

After unloading, the truck is weighed empty to establish the amount of the load. The amount of the sale depends on current market price. A ticket is added to the farmer's account.

-

The rear door to the office is located to the right in the photograph.

-

The scales are connected to an electronic weighing system in the office.

-

Five employees run the elevator operations. Merle and Clay are in charge of outside tasks. There are two secretaries, Sue and Evon, as well as a general manager, Ed Nowlin. The elevator provides a central meeting place for some members of the farm community.

-

The Escambia Grain elevator is about 5 stories high and can be seen for miles around.

This is the only farm cooperative grain elevator in northwest Florida.

This is the only farm cooperative grain elevator in northwest Florida. There are three main buildings in the complex. The office is on the left, the grain elevator is immediately behind the office building and the fertilizer house is on the right of the photograph.

There are three main buildings in the complex. The office is on the left, the grain elevator is immediately behind the office building and the fertilizer house is on the right of the photograph. The elevator is approximately 100 feet tall. There are six silos or individual storage bins attached to the main building.

The elevator is approximately 100 feet tall. There are six silos or individual storage bins attached to the main building. The opening under the main structure is the main access for loading and unloading truck loads of farm products.

The opening under the main structure is the main access for loading and unloading truck loads of farm products. Trucks enter and stop at the office for a weigh-in to establish the amount of product before unloading.

Trucks enter and stop at the office for a weigh-in to establish the amount of product before unloading. The soybeans are unloaded into "the pit", a 30' underground storage space. Commodities are purchased from the farmers, stored and sold to consumers in amounts up to 5 tons.

The soybeans are unloaded into "the pit", a 30' underground storage space. Commodities are purchased from the farmers, stored and sold to consumers in amounts up to 5 tons. The same area serves as a loading bay. A flow of corn is released from the storage silo. Customers range from hunters and farmers to sales of corn by the truckload, shipped overseas from the port in nearby Mobile.

The same area serves as a loading bay. A flow of corn is released from the storage silo. Customers range from hunters and farmers to sales of corn by the truckload, shipped overseas from the port in nearby Mobile. This small elevator services the main silo.

This small elevator services the main silo. The pipes feed into 18 different bins, storing individual items, such as, wheat oats, milo, soybeans and corn. Corn is the main item in storage at the elevator.

The pipes feed into 18 different bins, storing individual items, such as, wheat oats, milo, soybeans and corn. Corn is the main item in storage at the elevator. The conveyor belt moves corn up to the top floor of the grain elevator. The belt must be cleaned by hand.

The conveyor belt moves corn up to the top floor of the grain elevator. The belt must be cleaned by hand. The conveyor belt runs the length of the bins.

The conveyor belt runs the length of the bins. An auger turns the dispensing chute.

An auger turns the dispensing chute. The bins are numbered and the feeding tube is positioned over the correct storage area.

The bins are numbered and the feeding tube is positioned over the correct storage area. White corn dust covers surfaces in the elevator.

White corn dust covers surfaces in the elevator. A spectacular view of Walnut Hill can be seen from the top of the silos. Hundreds of acres of farmland stretch to the northern horizon.

A spectacular view of Walnut Hill can be seen from the top of the silos. Hundreds of acres of farmland stretch to the northern horizon. Fertilizer is stored, mixed and sold in a seperate building. The bags shown above are loaded by hand after customing the mixture of the elements, such as, amonium nitrate, potash, etc.

Fertilizer is stored, mixed and sold in a seperate building. The bags shown above are loaded by hand after customing the mixture of the elements, such as, amonium nitrate, potash, etc. The bobcat is used to load scoops of ingredients in the fertilizer mix.

The bobcat is used to load scoops of ingredients in the fertilizer mix. Clay Stuckey demonstrates one of the tasks in the fertilizer house. The fertilizer is dumped into this grate. A scale weighs the material and it is mixed in a hopper. The finished product is distributed by truckload or by 50 pound bag.

Clay Stuckey demonstrates one of the tasks in the fertilizer house. The fertilizer is dumped into this grate. A scale weighs the material and it is mixed in a hopper. The finished product is distributed by truckload or by 50 pound bag. Pre-packaged materials in 50 pound bags are stored in the building adjacent to the front office. The bags contain fertilizer and seed, as well as feed for any livestock.

Pre-packaged materials in 50 pound bags are stored in the building adjacent to the front office. The bags contain fertilizer and seed, as well as feed for any livestock. After unloading, the truck is weighed empty to establish the amount of the load. The amount of the sale depends on current market price. A ticket is added to the farmer's account.

After unloading, the truck is weighed empty to establish the amount of the load. The amount of the sale depends on current market price. A ticket is added to the farmer's account. The rear door to the office is located to the right in the photograph.

The rear door to the office is located to the right in the photograph. The scales are connected to an electronic weighing system in the office.

The scales are connected to an electronic weighing system in the office. Five employees run the elevator operations. Merle and Clay are in charge of outside tasks. There are two secretaries, Sue and Evon, as well as a general manager, Ed Nowlin. The elevator provides a central meeting place for some members of the farm community.

Five employees run the elevator operations. Merle and Clay are in charge of outside tasks. There are two secretaries, Sue and Evon, as well as a general manager, Ed Nowlin. The elevator provides a central meeting place for some members of the farm community. The Escambia Grain elevator is about 5 stories high and can be seen for miles around.

The Escambia Grain elevator is about 5 stories high and can be seen for miles around. One Tank of Gas

One Tank of Gas