-

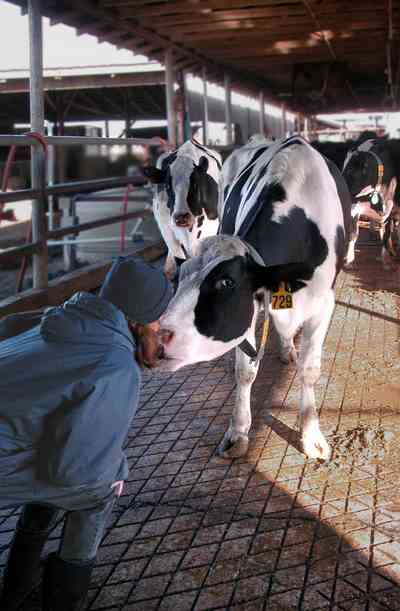

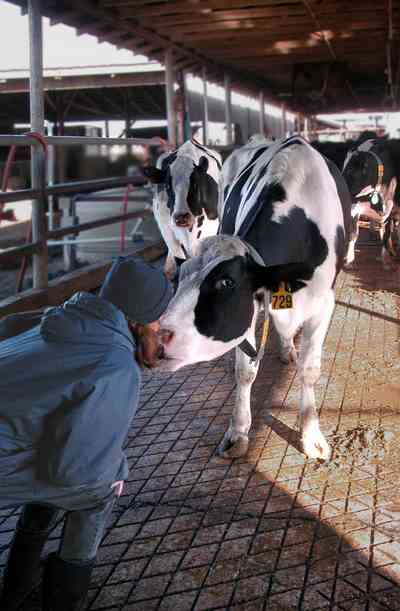

Steve Matthews feeds treats to the cows.

-

The south road is lined by an avenue of young live oak trees.

-

Dan Stewart and associates act out a number from the movie, "Brother Where Art Thou".

-

Bruce and Melvin Holland are standing in one of the corn fields where the current crop is Silver King corn.

-

Melvin Holland samples the Silver King corn.

-

Diane Holland cleans the Silver King corn. She is planning a cream style corn recipe.

-

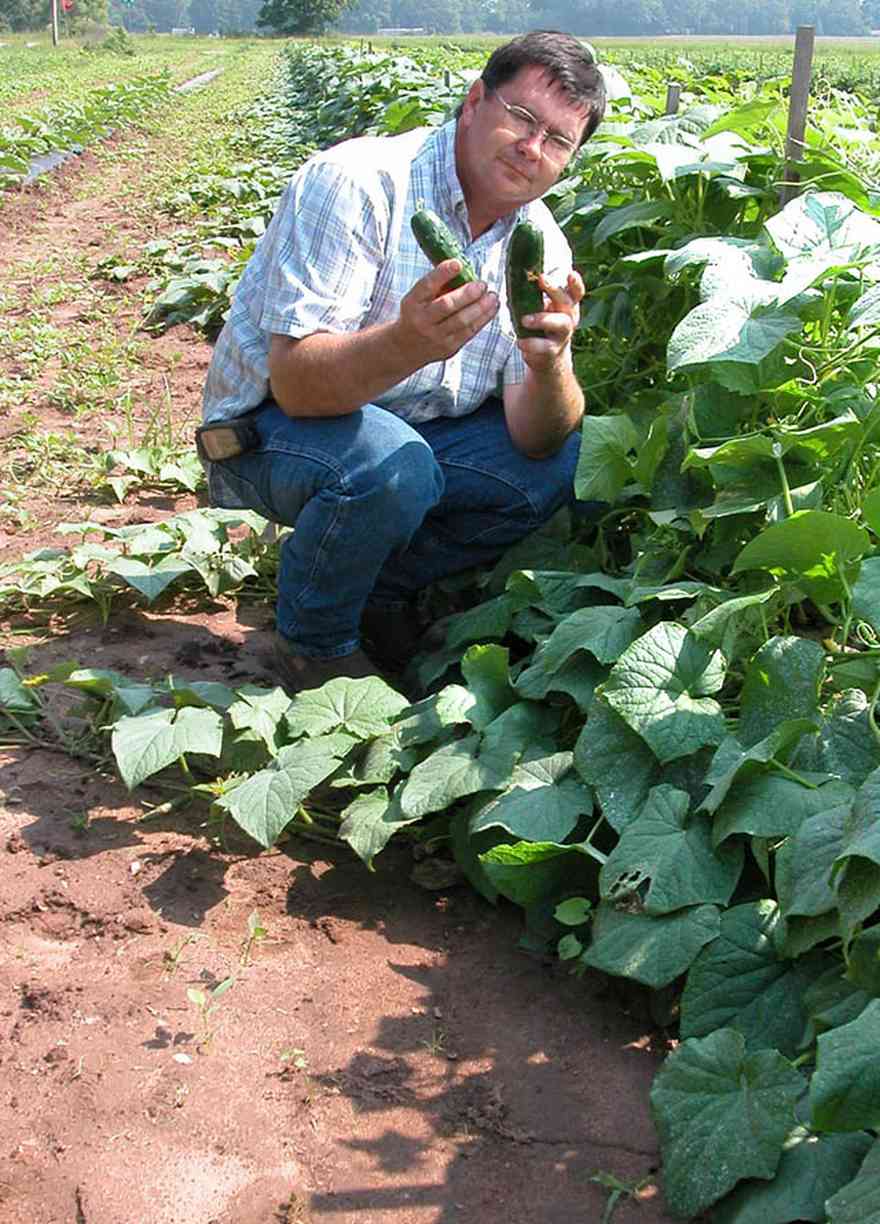

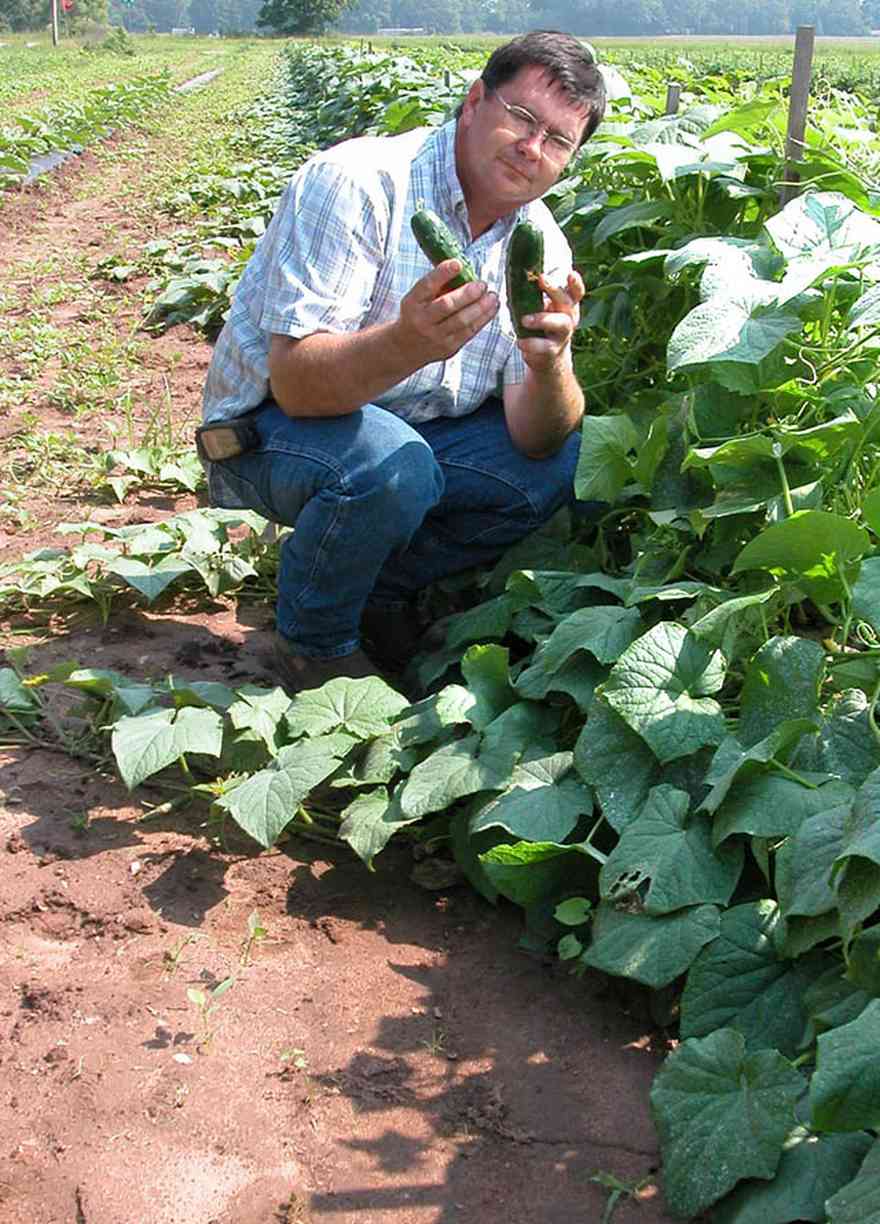

Produce such as, the cucumbers displayed by Bruce Holland is sold at the nearby barn.

-

Bruce Holland demonstrates soil quality in one of the north fields. The tilled area represents about five acres.

-

The field is being prepared for the next crop. Soil composition varies widely from field to field. The soil in this area has a high organic content. Soils are composed of sand, clay and organic materials.

-

The entrance to the barn and house is on the far right of the photograph. The 5 acre tilled field can be seen on the other side of the road.

-

A crew of local workers pick the beans.

-

The Bruce Holland farm complex is located on Homer Holland Road in Santa Rosa County, Florida. The peach trees seen in the photo produce about six bushels/60 pounds or 120 one-half pound peaches per tree.

-

Bruce Holland is seen in the foreground of his peach orchard in northwest Florida. The trees have been planted in symmetrical rows every year for the past six years. The orchard has approximately 200 trees, all bearing fruit.

-

The immature peaches shown above will be ready for picking in May and June, depending on the variety of tree. Mr. Holland also grows cantelopes, watermelons, butterbeans, peas, peanuts, and cotton. He has a booming retail business located out of his barn. The vegetable and fruit havest begins in May with the sale of peaches, cantelopes, and watermelons.

-

-

Bruce Holland inspects the cucumbers planted along a low fence.

-

Green peanuts are available.

-

Yellow crookneck squash grow in the garden south of the main barn.

-

Royal Star and Starbright Watermelons are the varieties of watermelons grown for harvest.

-

This 15 acre field was planted in butterbeans. It is irrigated with water from a nearby holding pond.

-

The irrigation line bisects a thirty acre field. The southern portion, show above, has been planted with pumpkins. The line of deciduous trees grow along Homer Holland Road.

-

The Holland farmhouse can be seen through the trees. The driveway is typical of dirt roads and driveways which are composed of red clay.

-

Watermelons grow best on a sandy loam soil.

-

Today there are more than 100 different varieties of watermelons. The flesh may be red, pink, orange or yellow.

-

The sweetest watermelons grow during long hot summers.

-

Ninety percent of watermelon is water.

-

Watermelon vines require considerable space. Seeds are planted one inch deep in hills spaced 6 feet apart. As the watermelon plants grows, the vines converge and the field becomes a sea of green vines.

-

The watermelon require a long growing season with relatively high temperatures. Daytime temperatures between 70 and 80 degrees F and nighttime temperatures between 65 and 70 degrees F are ideal.

-

Probably the most important indicator of ripeness is the underside which sets on the ground. Turn the melon over. It should be yellow or creamy colored on the underside. If it is white or pale green the melon is not ready to harvest.

-

Once picked, uncut watermelon can be stored for about 2 weeks at room temperature.

-

The flesh of the melon should be deep colored with mature seeds. Most watermelons have dark brown or black seeds.

-

Harvesting is particularly critical because watermelons do not continue to ripen after they have been removed from the vine. They should be picked at full maturity.

-

Watermelons are low in calories and very nutritious. Watermelon is high in lycopene, second only to tomatoes.

-

Watermelon is also high in Vitamin C and Vitamin A, in the form of disease fighting beta-carotene. Research also suggests that the red pigmented foods provide this protection.

-

Sycamore trees line Highway 178 at Sundance Farm.

-

The range of the sycamore tree is northwest Florida and can be found throughout Santa Rosa and Escambia counties.

-

-

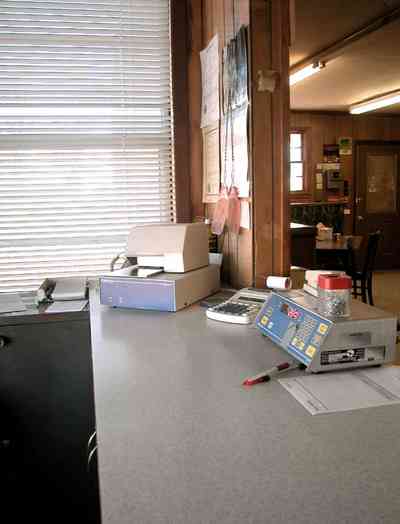

Mayor Barnes records the weight of his prize catch just before it is cleaned.

-

The silo in the background holds 15 tons of catfish food. Catfish food is fed in pellet form. It is a high protein diet composed of fish meal, soybeans, corn, and wheat. In the summer, the catfish at the Carpenter pond consume a ton of food each day.

-

Peanuts are grown on the 35 acre field adjacent to the homestead.

-

-

Pecan trees divide the homestead's driveway from the adjacent fields.

-

This is the only farm cooperative grain elevator in northwest Florida.

-

The opening under the main structure is the main access for loading and unloading truck loads of farm products.

-

Trucks enter and stop at the office for a weigh-in to establish the amount of product before unloading.

-

The soybeans are unloaded into "the pit", a 30' underground storage space. Commodities are purchased from the farmers, stored and sold to consumers in amounts up to 5 tons.

-

The same area serves as a loading bay. A flow of corn is released from the storage silo. Customers range from hunters and farmers to sales of corn by the truckload, shipped overseas from the port in nearby Mobile.

-

This small elevator services the main silo.

-

The pipes feed into 18 different bins, storing individual items, such as, wheat oats, milo, soybeans and corn. Corn is the main item in storage at the elevator.

-

The conveyor belt moves corn up to the top floor of the grain elevator. The belt must be cleaned by hand.

-

The conveyor belt runs the length of the bins.

-

An auger turns the dispensing chute.

-

The bins are numbered and the feeding tube is positioned over the correct storage area.

-

White corn dust covers surfaces in the elevator.

-

A spectacular view of Walnut Hill can be seen from the top of the silos. Hundreds of acres of farmland stretch to the northern horizon.

-

Fertilizer is stored, mixed and sold in a seperate building. The bags shown above are loaded by hand after customing the mixture of the elements, such as, amonium nitrate, potash, etc.

-

The bobcat is used to load scoops of ingredients in the fertilizer mix.

-

Clay Stuckey demonstrates one of the tasks in the fertilizer house. The fertilizer is dumped into this grate. A scale weighs the material and it is mixed in a hopper. The finished product is distributed by truckload or by 50 pound bag.

-

Pre-packaged materials in 50 pound bags are stored in the building adjacent to the front office. The bags contain fertilizer and seed, as well as feed for any livestock.

-

After unloading, the truck is weighed empty to establish the amount of the load. The amount of the sale depends on current market price. A ticket is added to the farmer's account.

-

The rear door to the office is located to the right in the photograph.

-

The scales are connected to an electronic weighing system in the office.

-

Five employees run the elevator operations. Merle and Clay are in charge of outside tasks. There are two secretaries, Sue and Evon, as well as a general manager, Ed Nowlin. The elevator provides a central meeting place for some members of the farm community.

-

Gobbler Road is in the Walnut Hill Community off Highway 97.

-

There are thousands of acres in cultivation in the Walnut Hill community planted in a variety of crops.

-

The 60 acre field is located on Highway 97 in the Walnut Hill community.

-

The pond is the foreground is one of many catfish ponds in the area. There are over 1,000 such ponds in the neighborhood.

-

There are cotton fields stretching for several miles on both sides of Kansas Road.

-

The corn crop will be used for silage to feed dairy cattle.

-

The heifer barn is on the right. The milking barn is in the center of the frame.

-

The cows are leaving the milking barn. They are milked in shifts of 16 cows. The entire herd is processed between 1:40 a.m. and 6:30 a.m. and again in the afternoon beginning at 1:00 p.m. finishing around 5:30 p.m..

-

There are three milkers who work in two shifts every day.

-

Jan McCune places the milking machine on the cow’s udders. The machine pulls a 30 pound pressure to complete the evacuation process in 5 to 15 minutes depending on the quanitity of milk.

-

Jan gets a “kiss” from her favorite Mama cow, No. 62. Cows wear collars and are named by number.

-

No. 62 is a friendly cow. The cows are in a holding pen, waiting to be called into the milking barn.

-

Cleaning the milking barn floor during shifts is a continous task.

-

Jan explains the gestation tabulator. The cycles and pregnancy of each cow is plotted.

-

George Van Pelt demonstrates the process of artificial insemination.

-

Tiny pumpkins and giant pumpkins are for sale at the Whitfield farm.

-

Stan Whitfield poises with his scarcrow near a pile of 60 pound pumpkins.

-

-

Highbush blueberries will grow upwards of 4 feet in height as mature plants and will yield large berries in late summer

Steve Matthews feeds treats to the cows.

Steve Matthews feeds treats to the cows. The south road is lined by an avenue of young live oak trees.

The south road is lined by an avenue of young live oak trees. Dan Stewart and associates act out a number from the movie, "Brother Where Art Thou".

Dan Stewart and associates act out a number from the movie, "Brother Where Art Thou". Bruce and Melvin Holland are standing in one of the corn fields where the current crop is Silver King corn.

Bruce and Melvin Holland are standing in one of the corn fields where the current crop is Silver King corn. Melvin Holland samples the Silver King corn.

Melvin Holland samples the Silver King corn. Diane Holland cleans the Silver King corn. She is planning a cream style corn recipe.

Diane Holland cleans the Silver King corn. She is planning a cream style corn recipe. Produce such as, the cucumbers displayed by Bruce Holland is sold at the nearby barn.

Produce such as, the cucumbers displayed by Bruce Holland is sold at the nearby barn. Bruce Holland demonstrates soil quality in one of the north fields. The tilled area represents about five acres.

Bruce Holland demonstrates soil quality in one of the north fields. The tilled area represents about five acres. The field is being prepared for the next crop. Soil composition varies widely from field to field. The soil in this area has a high organic content. Soils are composed of sand, clay and organic materials.

The field is being prepared for the next crop. Soil composition varies widely from field to field. The soil in this area has a high organic content. Soils are composed of sand, clay and organic materials. The entrance to the barn and house is on the far right of the photograph. The 5 acre tilled field can be seen on the other side of the road.

The entrance to the barn and house is on the far right of the photograph. The 5 acre tilled field can be seen on the other side of the road. A crew of local workers pick the beans.

A crew of local workers pick the beans. The Bruce Holland farm complex is located on Homer Holland Road in Santa Rosa County, Florida. The peach trees seen in the photo produce about six bushels/60 pounds or 120 one-half pound peaches per tree.

The Bruce Holland farm complex is located on Homer Holland Road in Santa Rosa County, Florida. The peach trees seen in the photo produce about six bushels/60 pounds or 120 one-half pound peaches per tree. Bruce Holland is seen in the foreground of his peach orchard in northwest Florida. The trees have been planted in symmetrical rows every year for the past six years. The orchard has approximately 200 trees, all bearing fruit.

Bruce Holland is seen in the foreground of his peach orchard in northwest Florida. The trees have been planted in symmetrical rows every year for the past six years. The orchard has approximately 200 trees, all bearing fruit. The immature peaches shown above will be ready for picking in May and June, depending on the variety of tree. Mr. Holland also grows cantelopes, watermelons, butterbeans, peas, peanuts, and cotton. He has a booming retail business located out of his barn. The vegetable and fruit havest begins in May with the sale of peaches, cantelopes, and watermelons.

The immature peaches shown above will be ready for picking in May and June, depending on the variety of tree. Mr. Holland also grows cantelopes, watermelons, butterbeans, peas, peanuts, and cotton. He has a booming retail business located out of his barn. The vegetable and fruit havest begins in May with the sale of peaches, cantelopes, and watermelons.

Bruce Holland inspects the cucumbers planted along a low fence.

Bruce Holland inspects the cucumbers planted along a low fence. Green peanuts are available.

Green peanuts are available. Yellow crookneck squash grow in the garden south of the main barn.

Yellow crookneck squash grow in the garden south of the main barn. Royal Star and Starbright Watermelons are the varieties of watermelons grown for harvest.

Royal Star and Starbright Watermelons are the varieties of watermelons grown for harvest. This 15 acre field was planted in butterbeans. It is irrigated with water from a nearby holding pond.

This 15 acre field was planted in butterbeans. It is irrigated with water from a nearby holding pond. The irrigation line bisects a thirty acre field. The southern portion, show above, has been planted with pumpkins. The line of deciduous trees grow along Homer Holland Road.

The irrigation line bisects a thirty acre field. The southern portion, show above, has been planted with pumpkins. The line of deciduous trees grow along Homer Holland Road. The Holland farmhouse can be seen through the trees. The driveway is typical of dirt roads and driveways which are composed of red clay.

The Holland farmhouse can be seen through the trees. The driveway is typical of dirt roads and driveways which are composed of red clay. Watermelons grow best on a sandy loam soil.

Watermelons grow best on a sandy loam soil. Today there are more than 100 different varieties of watermelons. The flesh may be red, pink, orange or yellow.

Today there are more than 100 different varieties of watermelons. The flesh may be red, pink, orange or yellow. The sweetest watermelons grow during long hot summers.

The sweetest watermelons grow during long hot summers. Ninety percent of watermelon is water.

Ninety percent of watermelon is water. Watermelon vines require considerable space. Seeds are planted one inch deep in hills spaced 6 feet apart. As the watermelon plants grows, the vines converge and the field becomes a sea of green vines.

Watermelon vines require considerable space. Seeds are planted one inch deep in hills spaced 6 feet apart. As the watermelon plants grows, the vines converge and the field becomes a sea of green vines. The watermelon require a long growing season with relatively high temperatures. Daytime temperatures between 70 and 80 degrees F and nighttime temperatures between 65 and 70 degrees F are ideal.

The watermelon require a long growing season with relatively high temperatures. Daytime temperatures between 70 and 80 degrees F and nighttime temperatures between 65 and 70 degrees F are ideal. Probably the most important indicator of ripeness is the underside which sets on the ground. Turn the melon over. It should be yellow or creamy colored on the underside. If it is white or pale green the melon is not ready to harvest.

Probably the most important indicator of ripeness is the underside which sets on the ground. Turn the melon over. It should be yellow or creamy colored on the underside. If it is white or pale green the melon is not ready to harvest. Once picked, uncut watermelon can be stored for about 2 weeks at room temperature.

Once picked, uncut watermelon can be stored for about 2 weeks at room temperature. The flesh of the melon should be deep colored with mature seeds. Most watermelons have dark brown or black seeds.

The flesh of the melon should be deep colored with mature seeds. Most watermelons have dark brown or black seeds. Harvesting is particularly critical because watermelons do not continue to ripen after they have been removed from the vine. They should be picked at full maturity.

Harvesting is particularly critical because watermelons do not continue to ripen after they have been removed from the vine. They should be picked at full maturity. Watermelons are low in calories and very nutritious. Watermelon is high in lycopene, second only to tomatoes.

Watermelons are low in calories and very nutritious. Watermelon is high in lycopene, second only to tomatoes. Watermelon is also high in Vitamin C and Vitamin A, in the form of disease fighting beta-carotene. Research also suggests that the red pigmented foods provide this protection.

Watermelon is also high in Vitamin C and Vitamin A, in the form of disease fighting beta-carotene. Research also suggests that the red pigmented foods provide this protection. Sycamore trees line Highway 178 at Sundance Farm.

Sycamore trees line Highway 178 at Sundance Farm. The range of the sycamore tree is northwest Florida and can be found throughout Santa Rosa and Escambia counties.

The range of the sycamore tree is northwest Florida and can be found throughout Santa Rosa and Escambia counties.

Mayor Barnes records the weight of his prize catch just before it is cleaned.

Mayor Barnes records the weight of his prize catch just before it is cleaned. The silo in the background holds 15 tons of catfish food. Catfish food is fed in pellet form. It is a high protein diet composed of fish meal, soybeans, corn, and wheat. In the summer, the catfish at the Carpenter pond consume a ton of food each day.

The silo in the background holds 15 tons of catfish food. Catfish food is fed in pellet form. It is a high protein diet composed of fish meal, soybeans, corn, and wheat. In the summer, the catfish at the Carpenter pond consume a ton of food each day. Peanuts are grown on the 35 acre field adjacent to the homestead.

Peanuts are grown on the 35 acre field adjacent to the homestead.

Pecan trees divide the homestead's driveway from the adjacent fields.

Pecan trees divide the homestead's driveway from the adjacent fields. This is the only farm cooperative grain elevator in northwest Florida.

This is the only farm cooperative grain elevator in northwest Florida. The opening under the main structure is the main access for loading and unloading truck loads of farm products.

The opening under the main structure is the main access for loading and unloading truck loads of farm products. Trucks enter and stop at the office for a weigh-in to establish the amount of product before unloading.

Trucks enter and stop at the office for a weigh-in to establish the amount of product before unloading. The soybeans are unloaded into "the pit", a 30' underground storage space. Commodities are purchased from the farmers, stored and sold to consumers in amounts up to 5 tons.

The soybeans are unloaded into "the pit", a 30' underground storage space. Commodities are purchased from the farmers, stored and sold to consumers in amounts up to 5 tons. The same area serves as a loading bay. A flow of corn is released from the storage silo. Customers range from hunters and farmers to sales of corn by the truckload, shipped overseas from the port in nearby Mobile.

The same area serves as a loading bay. A flow of corn is released from the storage silo. Customers range from hunters and farmers to sales of corn by the truckload, shipped overseas from the port in nearby Mobile. This small elevator services the main silo.

This small elevator services the main silo. The pipes feed into 18 different bins, storing individual items, such as, wheat oats, milo, soybeans and corn. Corn is the main item in storage at the elevator.

The pipes feed into 18 different bins, storing individual items, such as, wheat oats, milo, soybeans and corn. Corn is the main item in storage at the elevator. The conveyor belt moves corn up to the top floor of the grain elevator. The belt must be cleaned by hand.

The conveyor belt moves corn up to the top floor of the grain elevator. The belt must be cleaned by hand. The conveyor belt runs the length of the bins.

The conveyor belt runs the length of the bins. An auger turns the dispensing chute.

An auger turns the dispensing chute. The bins are numbered and the feeding tube is positioned over the correct storage area.

The bins are numbered and the feeding tube is positioned over the correct storage area. White corn dust covers surfaces in the elevator.

White corn dust covers surfaces in the elevator. A spectacular view of Walnut Hill can be seen from the top of the silos. Hundreds of acres of farmland stretch to the northern horizon.

A spectacular view of Walnut Hill can be seen from the top of the silos. Hundreds of acres of farmland stretch to the northern horizon. Fertilizer is stored, mixed and sold in a seperate building. The bags shown above are loaded by hand after customing the mixture of the elements, such as, amonium nitrate, potash, etc.

Fertilizer is stored, mixed and sold in a seperate building. The bags shown above are loaded by hand after customing the mixture of the elements, such as, amonium nitrate, potash, etc. The bobcat is used to load scoops of ingredients in the fertilizer mix.

The bobcat is used to load scoops of ingredients in the fertilizer mix. Clay Stuckey demonstrates one of the tasks in the fertilizer house. The fertilizer is dumped into this grate. A scale weighs the material and it is mixed in a hopper. The finished product is distributed by truckload or by 50 pound bag.

Clay Stuckey demonstrates one of the tasks in the fertilizer house. The fertilizer is dumped into this grate. A scale weighs the material and it is mixed in a hopper. The finished product is distributed by truckload or by 50 pound bag. Pre-packaged materials in 50 pound bags are stored in the building adjacent to the front office. The bags contain fertilizer and seed, as well as feed for any livestock.

Pre-packaged materials in 50 pound bags are stored in the building adjacent to the front office. The bags contain fertilizer and seed, as well as feed for any livestock. After unloading, the truck is weighed empty to establish the amount of the load. The amount of the sale depends on current market price. A ticket is added to the farmer's account.

After unloading, the truck is weighed empty to establish the amount of the load. The amount of the sale depends on current market price. A ticket is added to the farmer's account. The rear door to the office is located to the right in the photograph.

The rear door to the office is located to the right in the photograph. The scales are connected to an electronic weighing system in the office.

The scales are connected to an electronic weighing system in the office. Five employees run the elevator operations. Merle and Clay are in charge of outside tasks. There are two secretaries, Sue and Evon, as well as a general manager, Ed Nowlin. The elevator provides a central meeting place for some members of the farm community.

Five employees run the elevator operations. Merle and Clay are in charge of outside tasks. There are two secretaries, Sue and Evon, as well as a general manager, Ed Nowlin. The elevator provides a central meeting place for some members of the farm community. Gobbler Road is in the Walnut Hill Community off Highway 97.

Gobbler Road is in the Walnut Hill Community off Highway 97. There are thousands of acres in cultivation in the Walnut Hill community planted in a variety of crops.

There are thousands of acres in cultivation in the Walnut Hill community planted in a variety of crops. The 60 acre field is located on Highway 97 in the Walnut Hill community.

The 60 acre field is located on Highway 97 in the Walnut Hill community. The pond is the foreground is one of many catfish ponds in the area. There are over 1,000 such ponds in the neighborhood.

The pond is the foreground is one of many catfish ponds in the area. There are over 1,000 such ponds in the neighborhood. There are cotton fields stretching for several miles on both sides of Kansas Road.

There are cotton fields stretching for several miles on both sides of Kansas Road. The corn crop will be used for silage to feed dairy cattle.

The corn crop will be used for silage to feed dairy cattle. The heifer barn is on the right. The milking barn is in the center of the frame.

The heifer barn is on the right. The milking barn is in the center of the frame. The cows are leaving the milking barn. They are milked in shifts of 16 cows. The entire herd is processed between 1:40 a.m. and 6:30 a.m. and again in the afternoon beginning at 1:00 p.m. finishing around 5:30 p.m..

The cows are leaving the milking barn. They are milked in shifts of 16 cows. The entire herd is processed between 1:40 a.m. and 6:30 a.m. and again in the afternoon beginning at 1:00 p.m. finishing around 5:30 p.m.. There are three milkers who work in two shifts every day.

There are three milkers who work in two shifts every day. Jan McCune places the milking machine on the cow’s udders. The machine pulls a 30 pound pressure to complete the evacuation process in 5 to 15 minutes depending on the quanitity of milk.

Jan McCune places the milking machine on the cow’s udders. The machine pulls a 30 pound pressure to complete the evacuation process in 5 to 15 minutes depending on the quanitity of milk. Jan gets a “kiss” from her favorite Mama cow, No. 62. Cows wear collars and are named by number.

Jan gets a “kiss” from her favorite Mama cow, No. 62. Cows wear collars and are named by number. No. 62 is a friendly cow. The cows are in a holding pen, waiting to be called into the milking barn.

No. 62 is a friendly cow. The cows are in a holding pen, waiting to be called into the milking barn. Cleaning the milking barn floor during shifts is a continous task.

Cleaning the milking barn floor during shifts is a continous task. Jan explains the gestation tabulator. The cycles and pregnancy of each cow is plotted.

Jan explains the gestation tabulator. The cycles and pregnancy of each cow is plotted. George Van Pelt demonstrates the process of artificial insemination.

George Van Pelt demonstrates the process of artificial insemination. Tiny pumpkins and giant pumpkins are for sale at the Whitfield farm.

Tiny pumpkins and giant pumpkins are for sale at the Whitfield farm. Stan Whitfield poises with his scarcrow near a pile of 60 pound pumpkins.

Stan Whitfield poises with his scarcrow near a pile of 60 pound pumpkins.

Highbush blueberries will grow upwards of 4 feet in height as mature plants and will yield large berries in late summer

Highbush blueberries will grow upwards of 4 feet in height as mature plants and will yield large berries in late summer One Tank of Gas

One Tank of Gas